Research & Development

IN THE HEART OF EUROPE

Hardware, Software, Enclosure and Testing device development

Our highly qualified engineers can manage a project from the idea and requirements presented to us by a business partner to selecting suitable solutions, hardware and software development, mechanical and housing design, technical documentation, certification and developing testing tools to assure product quality. Furthermore we offer customer support and counselling throughout the entire process of developing, manufacturing, implementation and products lifespan which helps build a stable partnership.

AREAS OF CURRENT DEVELOPMENT IN COMMUNICATIONS

- Capturing and digitally processing data on embedded and PC systems.

- Digital wireless communication (SRD free band devices and WiFi).

- Development of communication devices.

- For communicating through GSM or CDMA networks 3G, 4G/LTE and 5G.

- Wireless internet oriented communication: GPRS, CDMA, 3G and 4G/LTE, 5G, WIFI point to point and Bluetooth.

- Communication through Ethernet networks and classic phone networks;

- Protocol data exchange (PPP, TCP/IP, FTP) at the embedded level.

- Development of data set transfer: USB, RS232, RS485, and RS422.

- Software and hardware development, that allows monitoring, programming and remote device setup.

SUPPORT AND OTHER DEVELOPMENT

- Device planning that is in compliance with international standards and experience in certifying electronics systems (EMC and product safety reports, CE certificates, certificates in accordance with the CB scheme).

- DSP, ARM, soft-core processors

- Multilayer circuit board (Tools: Altium designer, P-CAD, CamTastic)

- Modelings casings mechanical packaging (Tools: Solid Works)

- 3D modeling and prototype printing

- Power supplies, power converters including PV-inverters and PV-micro inverters

- Battery management and charge controllers.

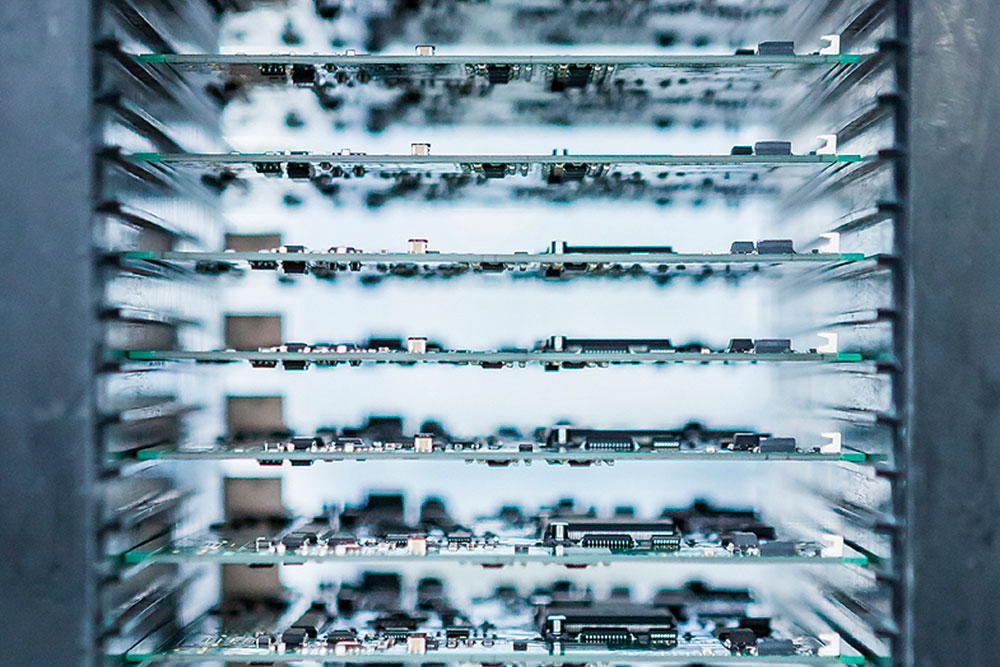

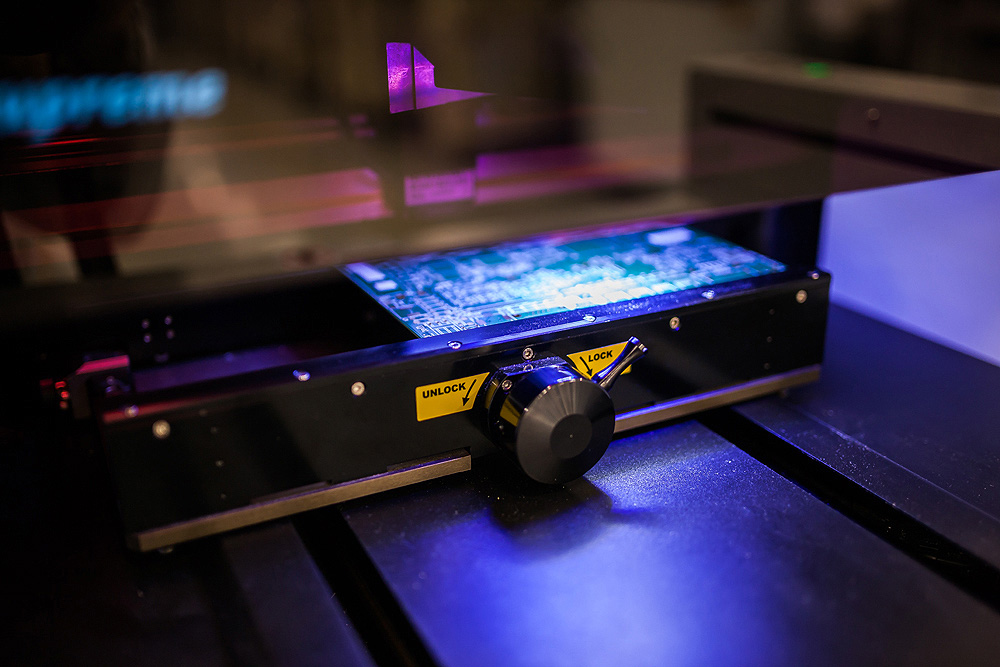

- Stacks Image 10

dedicated R&D, prototyping and specialty products

We have recently constructed a new facility dedicated to Development, Prototyping and small Specialty runs. Note that the capability to use various soldering alloys including lead is possible now. This increased capacity and capability is creating higher flexibility and better turn-a-round time for our customers. No longer is the mass production line interrupted for specialty and/or prototype items.

SMT d. o. o.

Liminjanska 96

6320 Portorož – Slovenia EU

t +386 5 67 12 800

f +386 5 67 12 829

info@smt.si

subscribe to our newsletter for company updates and new projects!